Our Services

We design conveyor systems based on real world constraints—long belts, pipe conveyors, downhill systems, feeders, trippers, and plant layouts.

Our capabilities includes layout planning, mechanical and structural design, simulations, retrofit engineering, and documentation.

We support both new installations and systems that need fixing.

Conveyor and Equipment Design

We design overland, pipe, and downhill conveyors, Conveyors with horizontal and vertical curves. Designs are based on terrain profiles, loading conditions, and material characteristics.

Static and dynamic analysis is carried out using specialized software

Layouts are optimized for take-up selection, power distribution, braking, and starting conditions.

Chute interfaces, gallery routing, and transfer tower loads are considered during early-stage layout to ensure structural integration.

Simulation and Analysis

We carry out static and dynamic analysis for overland, downhill, and pipe conveyors to validate belt tension, take-up response, and load distribution.

Drive sizing, power sharing, and braking performance are evaluated under various operating conditions using simulation tools to ensure stable and reliable system behavior.

We also perform finite element analysis (FEA) for pulleys, chutes, and support structures where required.

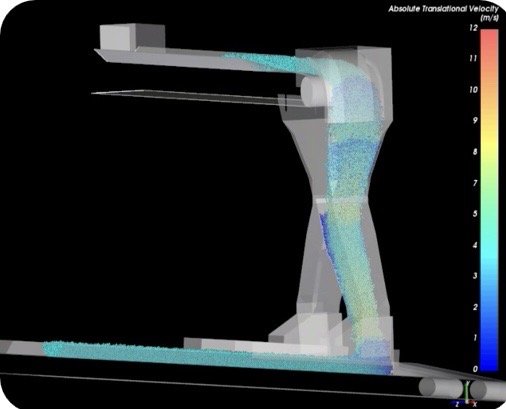

DEM & Chute Flow Studies

We use Discrete Element Modelling (DEM) to simulate material flow through transfer chutes, hoppers, and other flow zones.

Our simulations help verify material trajectory, reduce spillage and dust, and optimise liner placement and impact geometry.

We analyse flowability, buildup, wear zones, and particle degradation to fine-tune geometry before fabrication.

DEM studies are carried out for both new designs and modifications to existing systems, ensuring that flow issues are addressed early and accurately.

Augmentation and Reverse Engineering

We use Discrete Element Modelling (DEM) to simulate material flow through transfer chutes, hoppers, and other flow zones.

Our simulations help verify material trajectory, reduce spillage and dust, and optimise liner placement and impact geometry.

We analyse flowability, buildup, wear zones, and particle degradation to fine-tune geometry before fabrication.

DEM studies are carried out for both new designs and modifications to existing systems, ensuring that flow issues are addressed early and accurately.

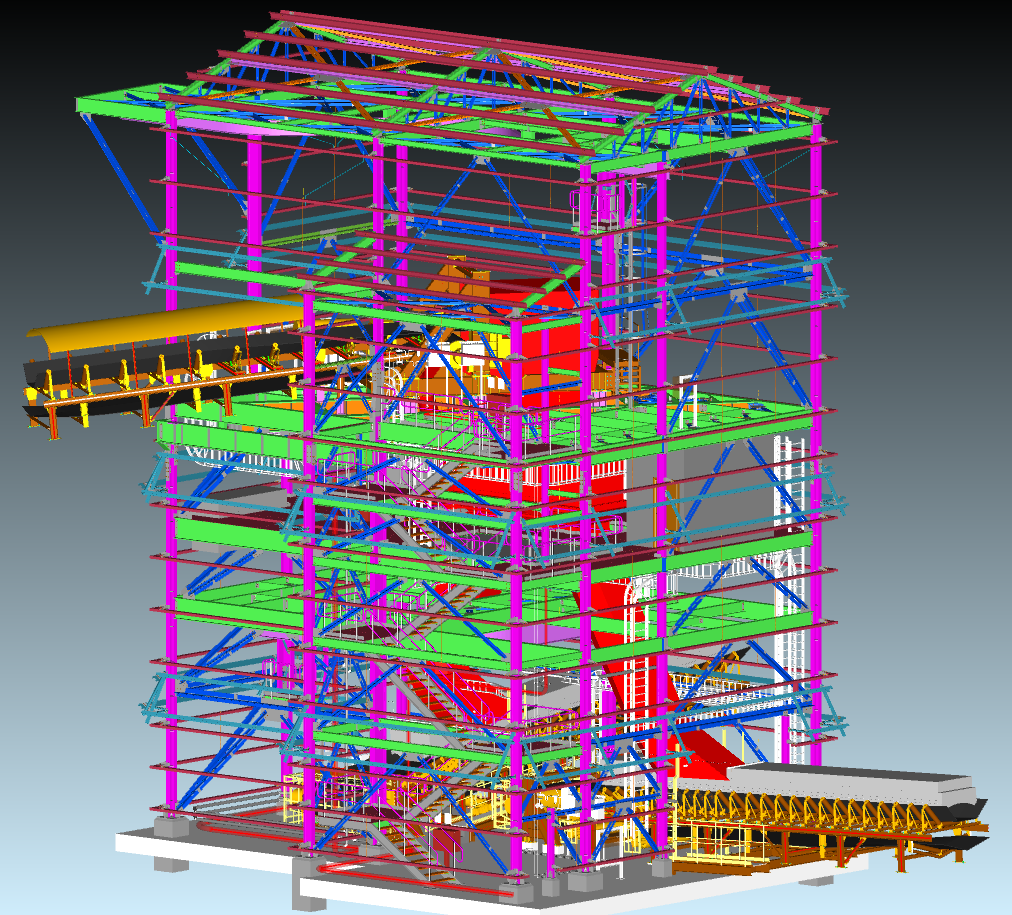

3D Modelling & Visualisations

We develop 3D models of conveyors, chutes, shuttle conveyors, and structural systems to validate fit, clearance, and overall integration within the plant layout.

Depending on project and client requirements, we use tools like Tekla, Navisworks, Advance Steel or SolidWorks to align with preferred platforms and ensure seamless coordination across disciplines.

We support multi-discipline integration and provide exportable models for BIM workflows, drawing extraction, and client or vendor use as needed.

These models are especially valuable in tight or retrofit environments where accuracy and early clash detection are critical.

Engineering Documentation and Proof Checking

We prepare engineering documentation packages for proposals, execution, and technical review—including GA drawings, BOQs, design basis reports, and fabrication-level deliverables.

Documentation can be provided to support vendor coordination, client submissions, and internal review processes, with structural calculations, load data etc., as required.

We also perform proof checking and review of third-party designs and drawings to verify compliance with project specifications.

Whether part of a full design package or a standalone review, we ensure what’s issued is complete, clear, and technically sound.

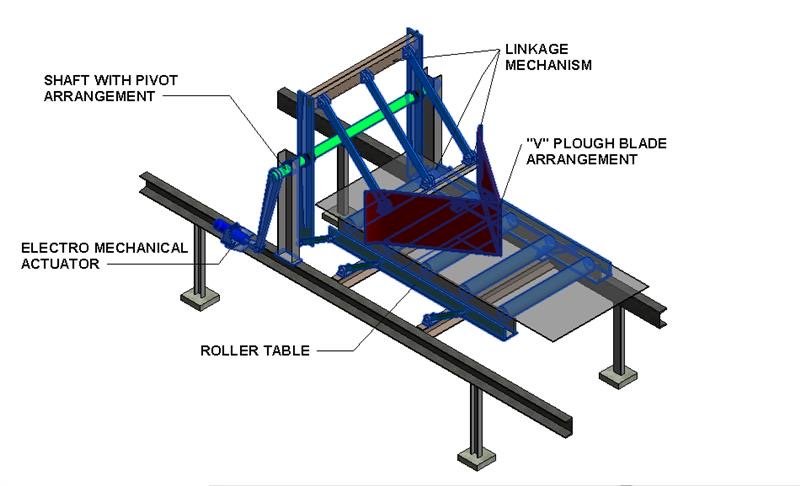

Specialized Engineering

We take on tasks that don’t fall under standard design packages—but often cause the most disruption for clients.

This includes feasibility studies for route and layout validation, geospatial software surveying, engineering audits of existing systems, and design optimisation to reduce wear, improve performance, or adapt to site constraints.

We also design non-standard mechanical systems like custom transfer points, diverter ploughs, and hybrid structures for tricky geometries or operating conditions.

These are short-scope, high-detail assignments that require fast, focused engineering support.